When designing or upgrading an electrical system, one of the most critical considerations is cable ampacity — the maximum amount of current a cable can safely carry without overheating. Ensuring that wires and cables can handle the electrical load is essential not only for system efficiency but also for preventing hazards such as fires and equipment failures. Whether in residential homes or large commercial buildings, several factors can significantly influence cable ampacity. Let’s explore the top ones.

Conductor Material

The type of conductor used — typically copper or aluminum — has a direct impact on cable ampacity. Copper, being a better conductor of electricity than aluminum, can carry more current for a given size. As a result, copper wires generally have a higher ampacity compared to aluminum wires of the same gauge. However, cost and weight considerations often influence the choice between the two, especially in commercial applications.

Insulation Type and Temperature Rating

Cable insulation is not just about protection from external damage; it also determines how much heat the cable can withstand. Different types of insulation have different temperature ratings, which directly affect cable ampacity. For instance, a cable with insulation rated for 90°C can carry more current than one rated for 60°C. Choosing the right insulation based on environmental conditions and application type is vital for safe performance.

Ambient Temperature

Cables are rated based on a standard ambient temperature, usually 30°C (86°F). If the cable is installed in an environment where the temperature is significantly higher, the heat dissipation capacity of the cable reduces, thereby lowering its ampacity. Both residential attics and commercial rooftops can experience high temperatures, making it necessary to derate the ampacity accordingly.

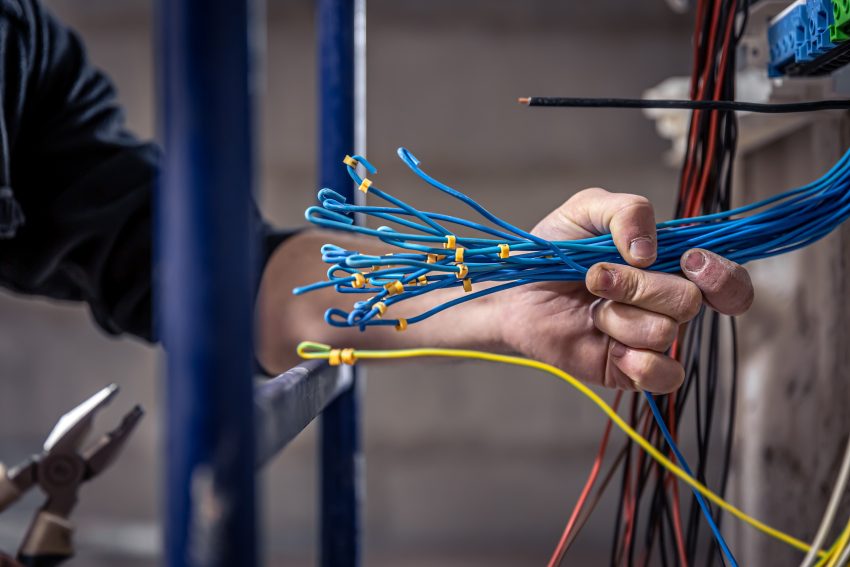

Installation Conditions and Grouping

The way cables are installed can greatly affect their ability to dissipate heat. For instance, cables installed in enclosed conduits or bundled together with other cables have less airflow, which restricts heat dissipation. This situation is common in commercial installations where space-saving cable trays or conduits are used. As a result, cable ampacity must be derated to compensate for limited heat dissipation.

Cable Length and Voltage Drop

Although not a direct factor on ampacity, long cable runs may lead to voltage drops, particularly the low voltage, residential systems. To preserve a high efficiency system, cables with more thickness might be needed and this in most cases increases the ampacity. Determining this relationship makes it easier when choice of the size of cable to be used in both planning residential and commercial installations is made.

Conclusion

Correctly determining and conceptualizing cable ampacity is crucial to safety and output of any electrical system. The current carrying capacity of the cable is dependent upon key factors anything that has to do with conductor material, type of insulation, ambient temperature, installation technique and length of the cable. The failure to consider any of these aspects may result in overheating, wastage of energy or a possible meltdown. You can be wiring a home or you plan a complex commercial wiring, it is a must to consult current standards and do intensive calculations to make sure you are up to standard and safe.