Safety and efficiency in the modern electrical systems are mainly concerned with the choice of cables to be used in transmitting power. The cable is the foundation of all electrical installation work, in residential buildings or in industrial plants, or even in major infrastructure projects. The cable current carrying capacity is one of the most important considerations when selecting a cable among the numerous factors to be considered. Knowing this means that the electrical network will operate reliably, safely, and with no unnecessary losses.

Understanding Cable Current Carrying Capacity

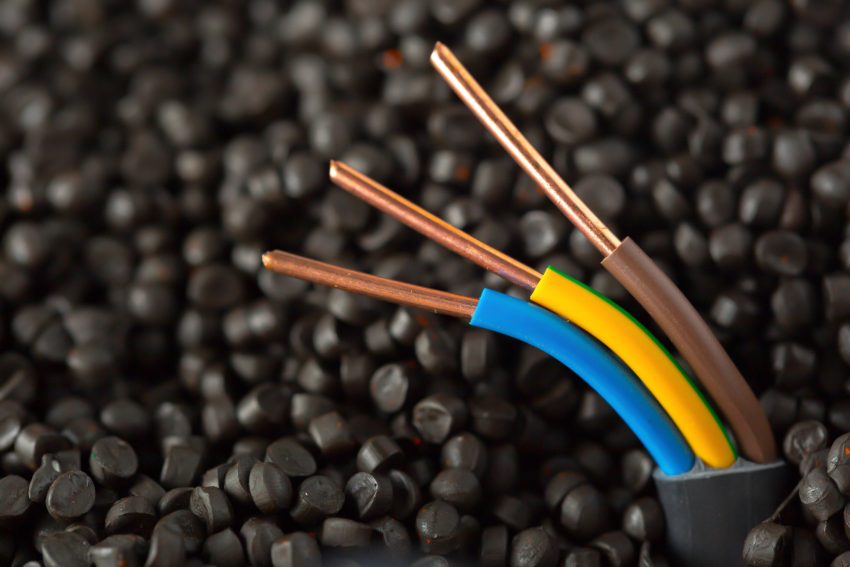

Cable current carrying capacity is the largest amount of electric current that a cable can deliver without overheating. Each cable is limited in a particular way, depending on its material, the type of insulation, and its cross-sectional dimension, the environment in which the cable is used. A high current strength will make the cable overheat, which will result in damage of the insulation, shortened life time or even fire.

As an example, a large cross-sectional area copper cable can carry a higher amount of current compared to a small cross-sectional area aluminum cable. Likewise, a cable in the open air will cool down more than a cable buried in the ground, and should thus be able to carry a larger capacity.

Why It Matters in Electrical Systems

The need to know the current carrying capacity of cables cannot be overemphasized. The decision to use a cable with a poor capacity may jeopardize the safety and dependability of a complete system. Some of the main reasons why it matters include the following:

Safety Against Fire Hazards – When a cable is overloaded, or required to carry higher current than it was designed to carry, it may overheat. This, not only destroys the insulation, but also plays a part in exposing electrical fires. Such risks are minimized by selecting capacity correctly.

Energy Efficiency – Cables that are over or under-sized can lead to problems in their efficiency. Although, the small size of the cable causes overheating and losses, large cables are more expensive and the correct current carrying capacity will ensure that there is a balance between safety and efficiency.

System Reliability – Electrical equipment is made to be used over time. Properly selected cables have the potential to carry the anticipated load as time moves by, thereby reducing the number of failures and power interruptions.

Compliance with Standards – Electrical codes and regulations stipulate the correct sizing of cables depending on the calculation of load. Looking at cable current carrying capacity is a way to meet these standards and prevent legal or inspection problems.

Factors Affecting Current Carrying Capacity

Several factors influence a cable’s capacity:

- Conductor Material– Copper generally carries more current than aluminum for the same size.

- Insulation Type– Different insulation materials have varying temperature tolerances.

- Installation Environment– Air, water, or underground installation affects heat dissipation.

- Ambient Temperature– Higher surrounding temperatures reduce carrying capacity.

Conclusion

Cable choice is a decision that has direct impacts on performance, safety and cost in any electrical project. Engineers and electricians can create efficient, reliable and safe systems by paying close attention to cable current carrying capacity. This concept is critical in protecting the integrity of the electrical network whether it is in a smaller household wiring project or large industrial installation.