Electrical panels are constructed to carry a given load. Consumption of these limits can result in high chances of overheating, equipment breakdown and electrical fire that become very dangerous. A lot of facilities are still adding new equipment, lamps, or temporary power outlets without checking the capacity of panels. An adequate safety assessment is useful in determining these risks before they can cause severe incidences.

Why Load Limits Exist

Any electrical panel is designed to a specific current rating depending on the size of the conductors, the breaker capacity and heat dissipation capacity. Anything above this rating leads to the overheating of the panel. This heat, with time, damages insulation, loosens connections and also decreases the breaker reliability. A Safety Assessment determines whether the real electrical demand falls within the design limits of the panel or not.

Neglect of load limits may not necessarily result in instant failure. Rather it causes progressive damage which can be noticed too late when a failure or even a fire breaks out.

Common Causes of Panel Overloading

The overloading of panels normally occurs because of the changes in operations and not due to poor design. Other common contributors are additional equipment, extended operating hours and temporary connections. Commonly at work places, extension boards and multiple tap-offs are installed without any modification of the calculations of loads. These modifications go around initial design assumptions.

A safety assessment is an examination of the present day use of the electrical system and not necessarily the way it was supposed to be used when installed.

Risks Created by Overloaded Panels

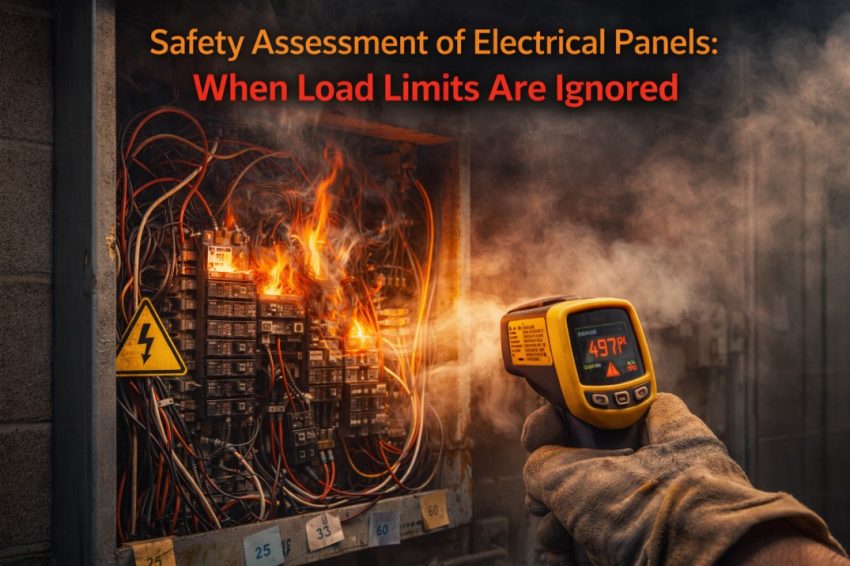

Congested panels have various safety risks. Any form of constant overheating may lead to breakers either tripping with different levels of unpredictability, or even not tripping when required. This exposes them to arc faults and short circuits. Extremely, fire in the panel enclosure may be caused by a breakdown of insulation.

Maintenance workers are not spared either. A panel that is overloaded possesses more energy of fault and this contributes to more serious burns or injuries in electrical work. A safety assessment is used to check the adequacy of protective devices and safety measures in the present conditions of loading.

Why Visual Checks Alone Are Not Enough

Numerous plants are using visual inspection to assess the condition of the panels. A panel can appear clean and well put together yet work with high risks of being dangerous. The heat accumulation is within conductors and connection, which is not discernible without appropriate measurement.

A Safety Assessment consists of load tests, thermal tests, and inspection of protection settings. This method brings out invisible stress that would not be detected in normal inspections.

Role of Inspections and Maintenance

They are important in controlling the panel loads by having regular checkups and preventive maintenance. The effects of overloading are aggravated by dust deposits, loose connections, and old components. Maintenance activities assist in preserving the panels in such a way that they are able to dissipate the heat and the protective devices are working properly.

A systematic safety assessment allows organizations to note the panels that need redistribution of the loads or breaker upgrades or expansion of the system. This will avoid reactive repairs and shorten downtimes.

Unauthorized Modifications Increase Risk

A significant cause of load limit violation is unauthorized amendments on the electrical panels. The safety of panels is affected by additions of breakers that have not been approved, inappropriate sizing of the cables, and bypassed protection. Such activities are usually not well documented or reviewed.

Such changes are pointed out by a safety assessment and guarantee that electrical work is done by qualified personnel. It also enhances responsibility and adherence to safety measures.

Conclusion

Omission of electrical panel load limits poses unacknowledged yet dangerous safety hazards. Overloading cannot lead to sudden failure, however, it gradually undermines the system and preconditions accidents. This is not by visual inspection and compliance checks only.

An in-depth safety assessment gives a good understanding of real electrical demand, overloaded panels, and gives recommendations on remedial measures. Organizations can prevent unnecessary risk of electricity by addressing the load limits before they pose risks to people, equipment, and business operations.

Also Read: Arc Flash Study: Why Passing an Electrical Audit Is Not Enough